Brochure

Download our document to see specific data of the service and how we work.

Let’s BEGIN

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

Sheet Piles

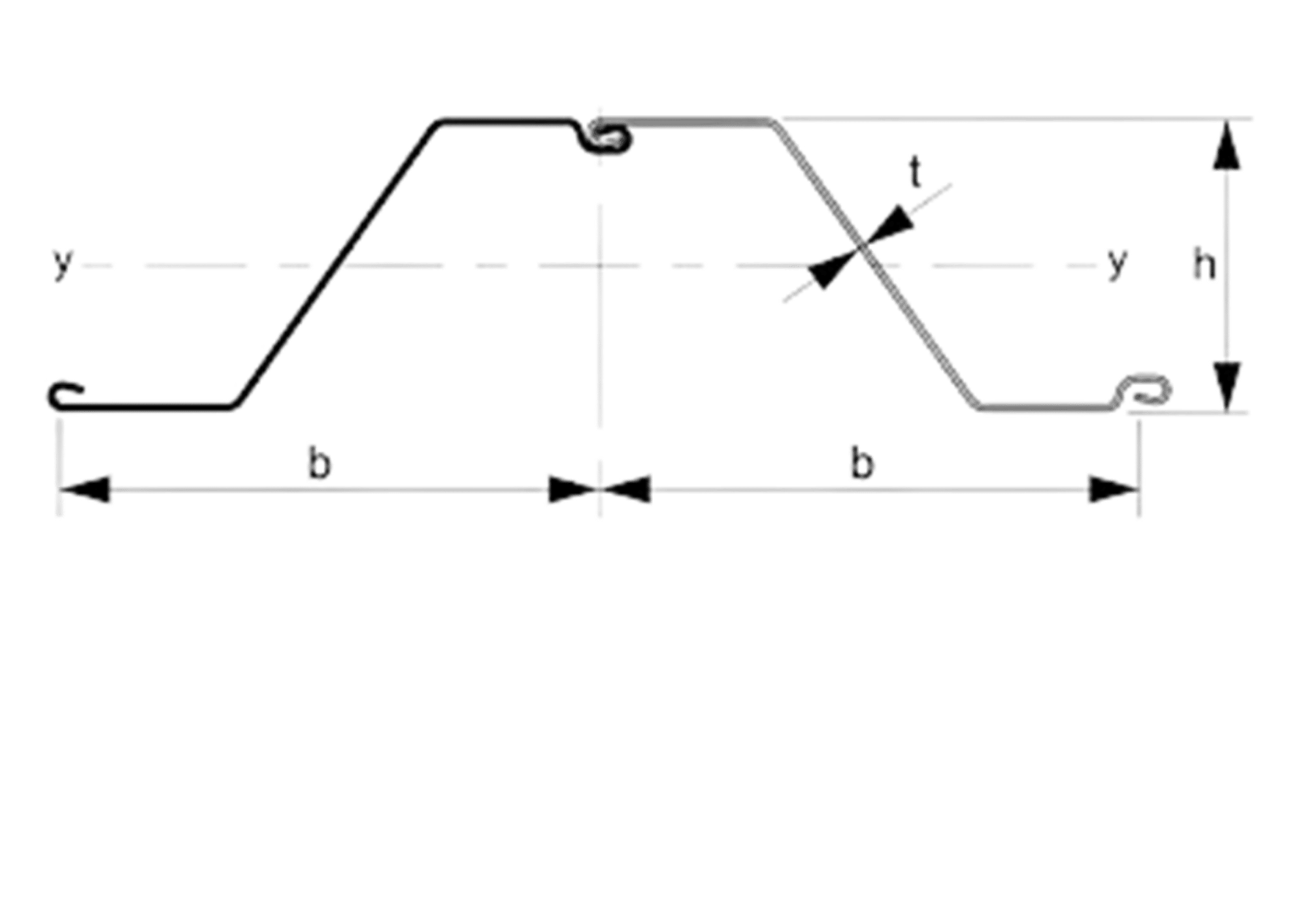

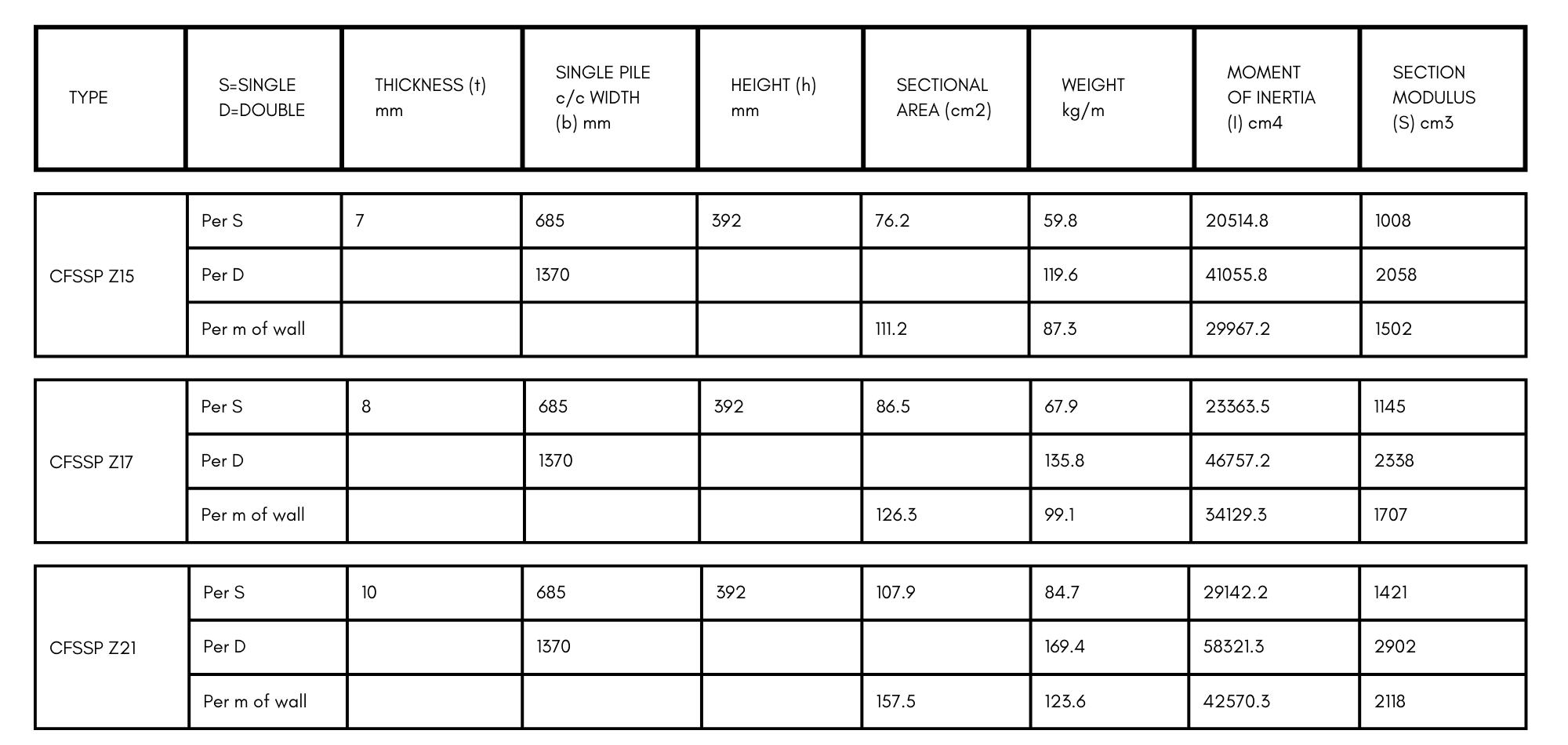

Sheet Pile is a row of piles driven side by side to retain earth or prevent seepage. Steel Sheet Piling has a connection “interlock” at both ends of the section. These interlocks connect with one another to form a continuous wall of Sheet Piling. Soil conditions may allow for the sections to be vibrated into the ground instead of being hammer driven. Typically these are designed to create a rigid barrier for earth and water, while resisting the lateral pressures of those bending forces. The shape or geometry of a section lends to the structural strength. In addition, the soil in which the section is driven has numerous mechanical properties that can affect the performance. The wall of sheeting provides excellent resistance to bending forces and is used to provide structural strength to a foundation.

Steel Sheet Piling is classified in two construc- tion applications, Permanent and Temporary. N. S Engineering Pvt Ltd carries a vast inventory of Sheet Pile, Cold-Formed Sheet Piling, all shapes can be used for combined walls are available in all grade qualities.

Applications

- River Embankments, Cofferdams

- Ground Water Diversion / Control

- Retaining / Containment Walls

- Ports and Harbor: embankments, break waters

- Flood/Coastal protection

- Weir Walls, Slope stabilization

- Earth retaining works, Tunnels etc.

Benefits of Galvanizing

- Hot Dip Galvanizing is the only protective coating process. of steel that provides long life, durability and predictive performance.

- Galvanizing is a once only process, committed to the concept of the maintenance-free use of steel, ensuring long service life and virtually eliminating disruptive maintenance.

- This long-term protection is well documented world-wide in terms ahead of any other protective coating, and galvanizing continues to find new applications in almost every field of engineering.

- In the presence of atmospheric moisture the zinc oxide film is quickly converted to zinc hydroxide, and carbon dioxide normally present in the air reacts to form basic zinc carbonates. These stable inert compounds resist further action and ensure long life for the protective galvanized coating.

- In warm dry atmospheres zinc is very stable. The patina formed during initial exposure remains intact preventing further reaction between the galvanized coating and the air, and protection continues indefinitely.

- Sea water Galvanized coatings perform relatively well in submerged sea water conditions which are severely corrosive to most protective systems. Dissolved salts present in sea water react with zinc to form a protective layer minimizing corrosive action.

- Near the sea coast the rate of corrosion is increased by the presence of soluble chlorides in the atmosphere. The performance of galvanized coatings relative to other protective systems is outstanding.

- When newly galvanized articles are immersed in pure water such as rain water, there are no dissolved salts present to form the film of insoluble compounds which normally protects the coating from further action. Where practical, this condition can be corrected by the addition to the water of controlled amounts of salts during initial immersion. Most natural waters contain sufficient dissolved salts to prevent initial attack and galvanized tanks and equipment give excellent service.

- In main supply of water of pH 6 to pH 8, calcium carbonate is normally present and this is precipitated onto the galvanized coating as an adherent calcium carbonate scale together with zinc corrosion products, forming an impervious layer. When sufficiently dense, this layer virtually stops corrosion of the coating, resulting in very long life in many domestic water systems.